Automotive Technology

Products

Top-class technology

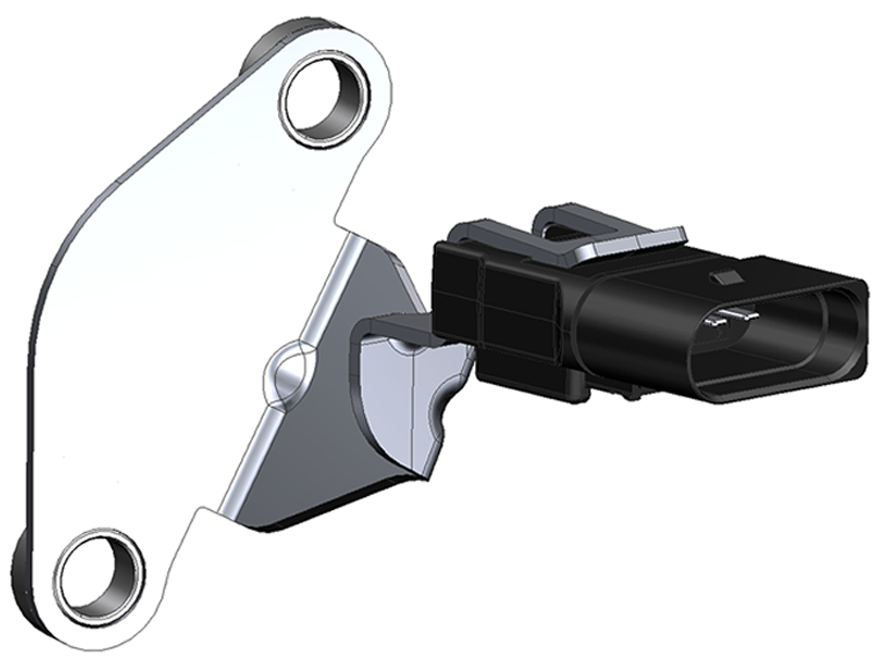

Brake pad wear indicator

The brake wear indicator is a sensor fitted in the brake pad, connected to the control unit in the vehicle, which informs the driver that the brake pad has reached its wear limit.

Our product range of sensors for measuring brake pad thickness extends from simple single-pole ground fault systems to multi-stage systems that monitor the wear condition of a brake pad over its entire service life.

Wiring harnesses

Wiring harnesses designed as axle cabling for brake pad wear indicators are an important part of the vehicle. We develop customer-specific solutions tailored to the specified interfaces with the aim of optimum routing in the area of application.

Customized solutions

We specialize in customized solutions that work reliably in the demanding environment of the brake and axle area.

Expertise

Full service at the highest level

As a manufacturer and global supplier to leading OEMs and TIER-1s, specializing in the production of brake pad wear indicators, supply lines and customer-specific special solutions in the demanding environment of the brake and axle sector, BOWA Automotive offers full competence in the entire product development process.

As a full-service provider, we are able to cover the entire product development process – from the initial idea to the design and manufacture of the finished product.

Our company

History, values, principles and locations

Many years of series production experience and constant progress in the field of high-temperature applications, especially in the brake sector, as well as know-how in plastic injection molding and cable processing technology have made BOWA Automotive a top player and sought-after supplier for the automotive industry.

With its products, BOWA Automotive meets the high requirements for functional and material safety. Our philosophy – reliability under extreme conditions – includes comprehensive testing and qualification of all components, supported by continuous simulations and tests. The full involvement of the quality department and a zero-defect strategy ensure that the high quality requirements of the automotive industry are met.

1977

founded

1979

first series production automobile

1990

start of production in Poland

15.000m²

production area

Download

Certificate & Downloads

Quality management is a consistent, systematic process that follows clearly defined criteria. Certified quality is not only a matter of course for BOWA Automotive, but also a promise to our customers and partners.

IATF 16949 is recognized worldwide by manufacturers in the automotive industry as the standard for quality management systems and proves our ability to meet customer requirements effectively and efficiently.