Expertise

Full service at the highest level

As a manufacturer and global supplier to the leading OEMs and TIER-1s, specializing in the production of brake pad wear indicators as well as supply lines and customer-specific special solutions in the demanding environment of the brake and axle area, BOWA Automotive offers full competence in the entire product development process.

As a full-service provider, we are able to cover the entire product development process – from the initial idea to the design and manufacture of the finished product. Our expertise in the processing of single strands and sheathed cables as well as thermoplastics, thermosets and elastomers enables us to produce high-quality, customer-specific parts and components from our extensive product portfolio.

Development

Customized solutions

The smooth running of today’s global automotive production lines depends on seamless digital exchange between car manufacturers and their supply chain. To ensure compliance with these requirements at all times, we rely on a combination of an ERP system and a direct EDI connection. Worldwide automatic delivery data exchange and electronic notification as well as KLT packaging and management are part of our basic logistics services. This efficient global logistics concept ensures that our components reach the customer on time, on schedule and in perfect quality.

As a full-service provider, we use APQP as a systematic approach to product development and offer customized solutions that cover the entire product development cycle – from conception and component design using CAD to in-house prototyping and the finished product. We rely on our in-house wire processing, injection molding and manufacturing expertise to ensure the highest quality and efficiency.

Project planning - APQP

Quality projects – jointly planned and secured

CAD

Complex design tasks – solved professionally

In-house prototyping

Flexible & fast – customized innovation

Environmental audits

Analysis down to the last detail

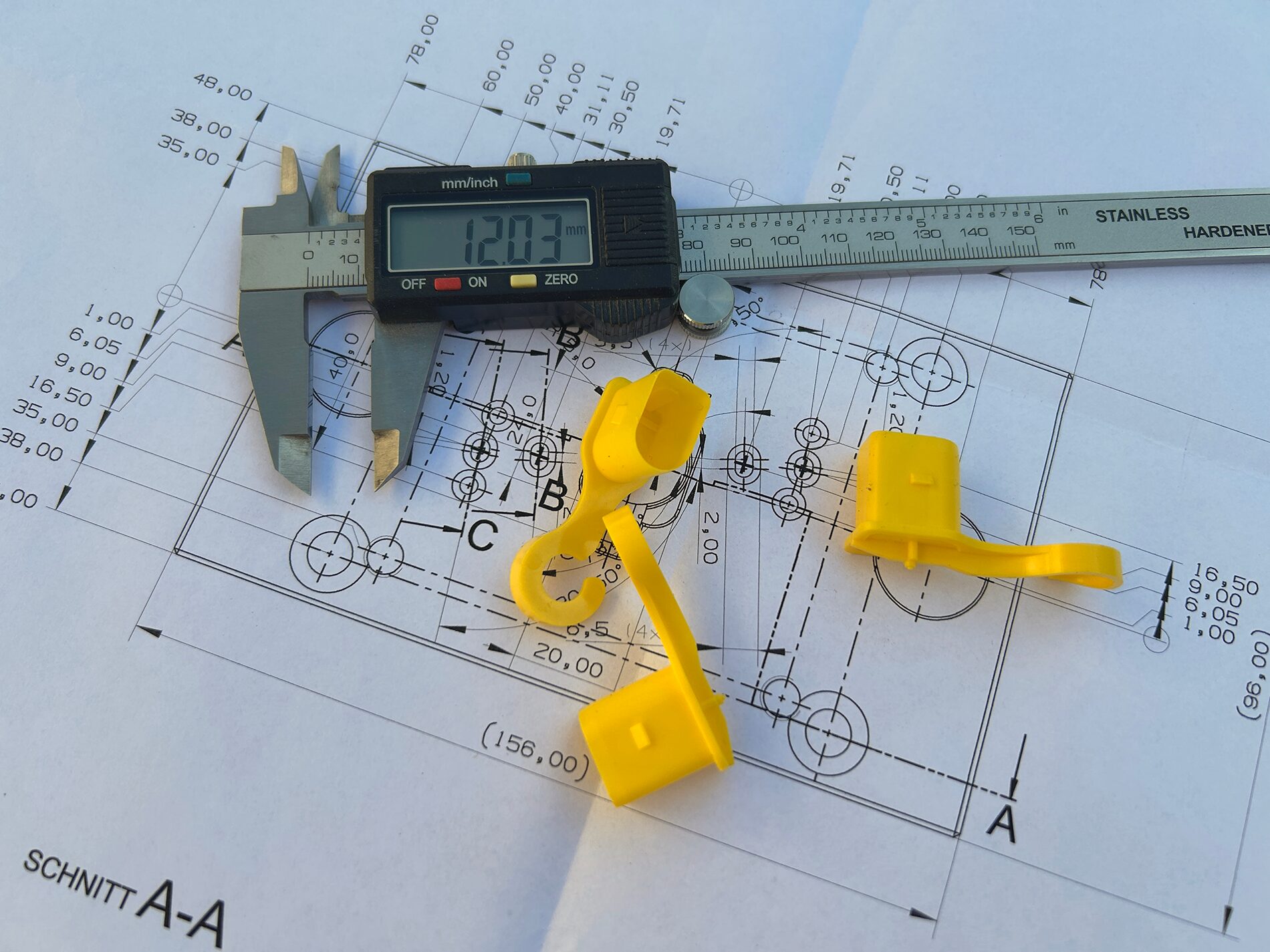

Toolmaking

Flexible and at short notice

In our in-house toolmaking department, we design and build tool molds from scratch. We have many years of experience in injection mold construction and maintenance as well as spare parts production and are able to implement even complex tasks. Our team is also able to manufacture assembly devices or machine spare parts in a targeted manner.

We use our extensive machine park, which includes 5-axis milling machines, wire erosion and eroding machines as well as lathes.

Each tool is subject to strict quality control in order to guarantee the required accuracy of the end product. The advantages are obvious: we can react flexibly and at short notice to changes in geometry requirements, carry out repairs to the tool or manufacture urgently needed spare parts.

This guarantees maximum production safety and reliability.

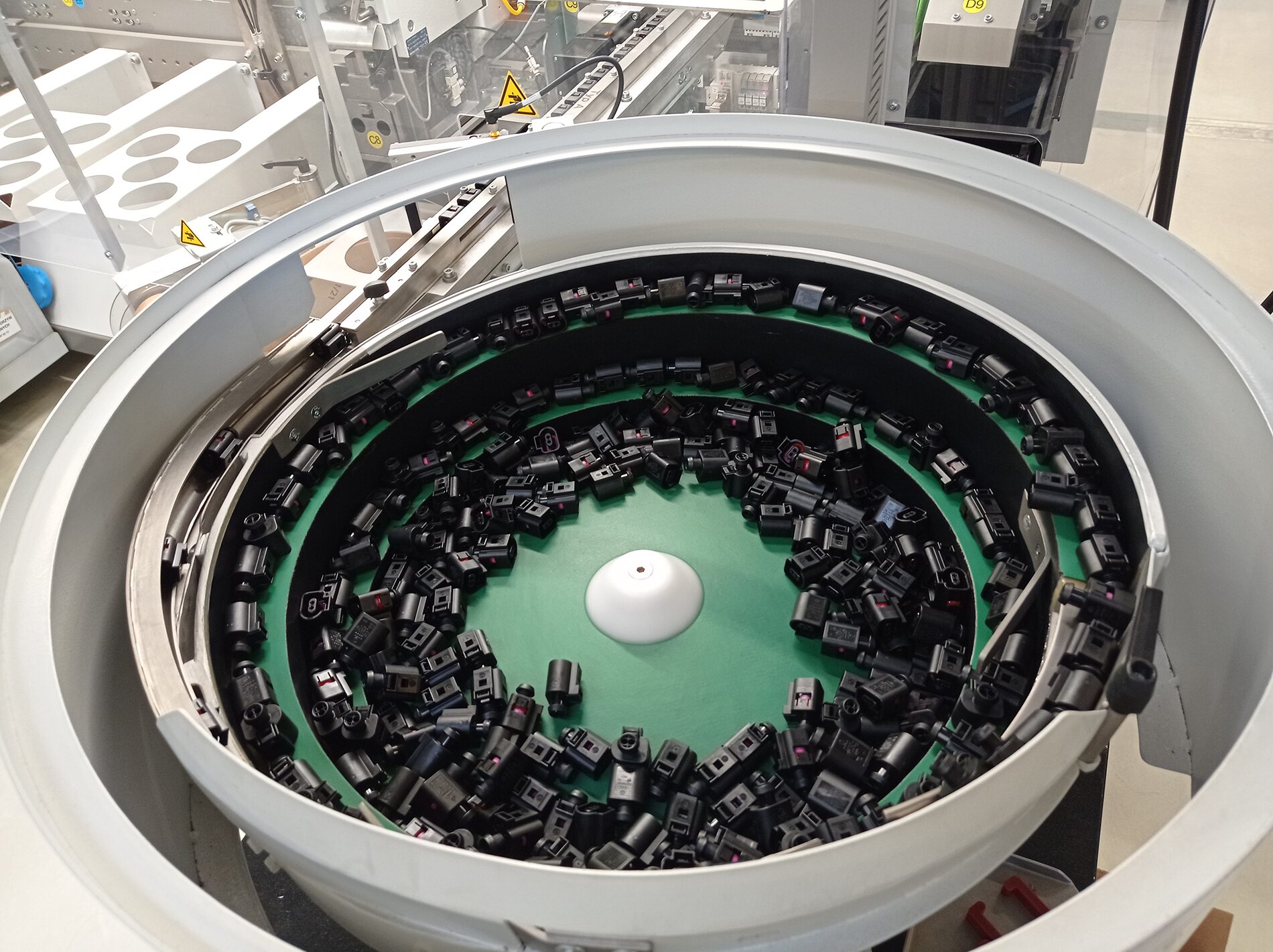

Production

High-quality and customized

Our expertise in wire processing and working with thermoplastics, thermosets and elastomers enables us to produce customized, high-quality parts and components that are precisely tailored to our customers’ needs.

Fully automatic and semi-automatic cutting and stripping processes are used to process single wires and sheathed cables for brake wear indicators and axle cabling. Specialized and complex automation solutions play a major role in cable processing, as they significantly improve the precision and speed of the manufacturing processes. The overmoulding of cables and the efficient production of free-falling plastic parts in conjunction with assembly processes are the key to success.

Thanks to our many years of production experience, we are able to manufacture high-quality, customer-specific parts and components for mass production.

Logistics

Fast & efficient

The smooth running of today’s global automotive production lines depends on seamless digital exchange between car manufacturers and their supply chain.

To ensure compliance with these requirements at all times, we rely on a combination of an ERP system and a direct EDI connection. Worldwide automatic delivery data exchange and electronic notification as well as KLT packaging and management are part of our basic logistic services.

This efficient global logistic concept ensures that our components reach the customer on time, on schedule and in perfect quality.

Quality

Is our top priority

Quality is our top priority and certifications serve as proof of our standards. Maintaining a consistently high level of quality is crucial to ensure customer satisfaction and to secure and strengthen our position in the market. Quality is not only present in our dialog with customers, but also runs through the entire value chain – from material purchasing to production and customer service. As part of our quality guidelines, we pursue a zero-defect strategy, supported by our technical equipment and the ongoing training of our staff.

Our philosophy includes comprehensive testing and qualification of all components, supported by continuous simulations and tests to maximize product performance. The involvement of the quality department from the outset ensures that the high quality requirements of the automotive industry are met.

Our commitment to quality is evidenced by industry-leading certifications that validate our processes and products and give our customers added confidence.